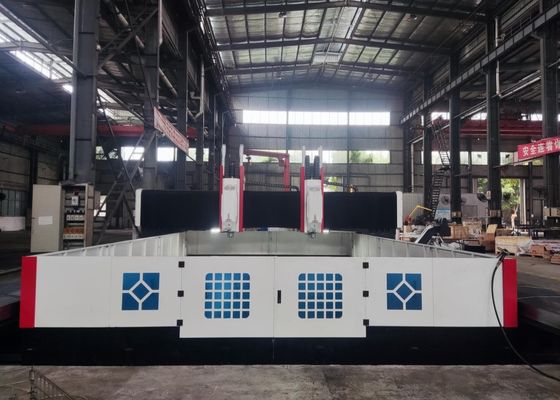

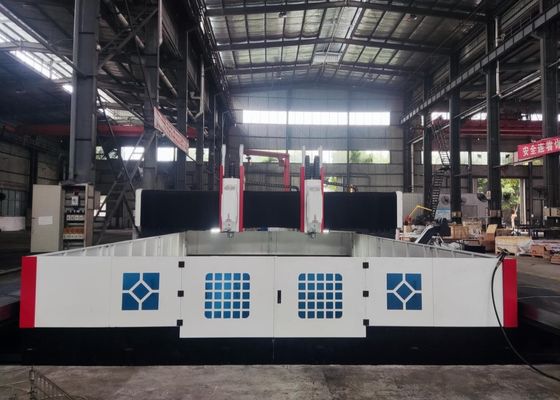

Robusta maszyna do wiercenia płytek CNC 6000x6000mm Rozmiar obrabiarków i 22 kW serwospindlowy silnik

Zastosowanie:

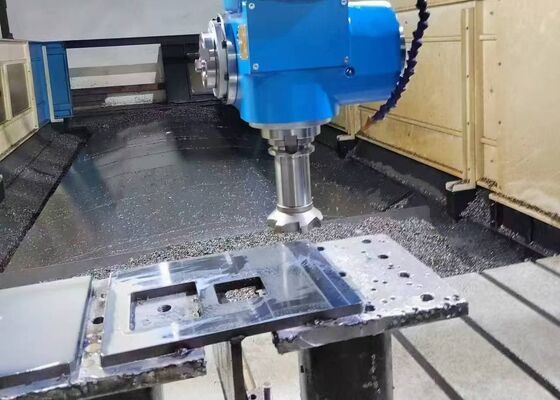

To urządzenie CNC do wiercenia i frezowania brzegów bramkowych jest przeznaczone przede wszystkim do wykonywania operacji wiercenia, rozwijania, szczelinowania, frezowania i wiercenia na kawałkach roboczych płyt i komponentach konstrukcyjnych.Zapewnia skuteczne działanie wiertnicze dla części roboczych, w tym płaszczyzn, dyski, pierścienie i płytki o grubości w granicach określonego zakresu skuteczności, zdolne do obróbki przez otwory i ślepe otworyjest kompatybilny zarówno z elementami z jednego materiału, jak i z materiałów złożonychDzięki technologii cyfrowego sterowania narzędzie maszynowe zapewnia wyjątkową wygodę operacyjną.obsługuje wymagania związane z przetwarzaniem wielu odmian, umożliwiając produkcję na dużą skalę.

Specyfikacje:

| Rozmiar obróbki |

LxW |

6000x6000 mm |

| Wysokość bramki |

800 mm

(Może być również określona w zależności od fundacji)

|

| Stolik roboczy |

Szerokość otworu w kształcie T |

28 mm |

| Głowa mocy wiertniczej |

Co to jest? |

2 |

| Węgiel spindlowy |

BT1pożyczalnia |

|

Maksymalna średnica wiercenia

(Zawsze stal węglowa)

|

Φ80 mm |

| Maksymalna grubość |

≤ 150 mm |

| Średnica wcisku |

M3-M36 |

| Prędkość spindala |

30~3000 obrotów/min |

| Siła silnika serwospindla |

22 kW |

| Odległość od dolnego końca węgla do stołu roboczego |

200-800 mm |

|

Ruch boczny głowicy napędowej(oś X)

|

Maksymalny bieg horyzontalny |

6000 mm |

| Prędkość ruchu bocznego |

0~8 obrotów/min |

| Siła serwomotora do ruchu bocznego |

2x4,2 kW |

|

Ruch wzdłużny bramki (oś Y)

|

Maksymalny bieg podawania |

6000 mm |

| Prędkość ruchu paszy |

0~8 m/min |

| Moc serwomotora zasilającego |

2x4,2 kW |

| Wyrównanie pomiarów |

Maks. uderzenie |

600 mm |

| Prędkość ruchu |

0~6 m/min |

| Siła serwomotora |

2x3,6kW (Hamowanie) |

| Dokładność pozycjonowania w trzech ośach |

X/Y/Z/A/B/C |

± 0,01/1000 mm |

| Dokładność pozycjonowania w trójosiowym powtarzaniu |

X/Y/Z/A/B/C |

± 0,01/1000 mm |

| Ogólna wielkość |

LxWxH |

11000x9500x4000 mm |

Struktura sprzętu:

Ta maszyna do wiertniania i oznakowania bramki CNC jest wyposażona głównie w stolik do pracy z żeliwa, ruchomą konstrukcję bramki, siodło przechodzące, głowicę do wiertniania,automatyczny system smarowania i ochrony, układ chłodzenia krążącego, układ sterowania numerycznego (NC) i układ sterowania elektrycznego.Podczas gdy wysokiej precyzji mechanizmy napędowe śruby kulkowej gwarantują lepszą dokładność pozycjonowania i doskonałą powtarzalność.

Cechy produktu

1Łóżko i stół roboczy:

Powierzchnia maszynowa jest wykonana z jednego kawałka odlewu żelaza szarego (HT250), podczas gdy bramka i podstawa wiązki bocznej są wykonane z wysokiej wytrzymałości struktur spawanych.Po wtórnym wygrzewaniu i starzeniu, dokonuje się precyzyjnego obróbki, aby osiągnąć wyjątkową sztywność dynamiczną i statyczną, skutecznie zapobiegając deformacji konstrukcyjnej.Powierzchnia stołu roboczego posiada precyzyjnie obrobione szczeliny w kształcie T, ułożone w optymalizowanym układzie, ułatwiające bezpieczne zaciskanie obrabiarków. Dwa precyzyjne przewodniki liniowe są zainstalowane po obu stronach podstawy łóżka,zapewnienie jednolitego rozkładu siły w wagonach przewodniczych i znaczne zwiększenie sztywności maszyny narzędziowej, wytrzymałość na rozciąganie i odporność na ciśnienie. System napędowy wykorzystuje serwomotor AC połączony z precyzyjnym zestawem śrub kulkowych do dwustronnej transmisji,umożliwiające płynne poruszanie się w osi Y bramkiZmiennego poziomowania śruby są strategicznie rozmieszczone na dnie łóżka, co umożliwia wygodną kalibrację poziomego ustawienia stołu roboczego.

2/ Mobilna brama:

Przenośny bramkarz zbudowany jest z materiału żelaza szarego (HT250), z dwoma ultra wysokoprężnymi, rolującymi się, liniowymi przewodnikami zintegrowanymi z przodu bramy.Zestaw precyzyjnych zestawów śrub kulkowych, w połączeniu z serwomotorem, ułatwia ruch osi X przesuwek głowicy napędowej.

3Przenośny siodło.

Siodło ruchome to precyzyjne konstrukcje z żeliwa odlewanego, wyposażone w dwa wysokoprężne linie kierownicze CNC, zestaw precyzyjnych wiertek kulkowych,i planetarnego reduktoru o wysokiej precyzji połączonego z serwomotoremJest on dodatkowo zintegrowany z cylindrem równoważącym azot, który równoważy wagę głowicy napędowej, aby zminimalizować obciążenie śruby kulkowej i wydłużyć jej żywotność.Ten komponent napędza głowicy mocy wiertniczej do wykonywania ruchu osi Z, umożliwiające podstawowe funkcje, w tym szybkie podawanie, działanie, szybkie cofanie i precyzyjne zatrzymanie.i możliwości przerwy w celu zwiększenia wydajności obróbki i elastyczności operacyjnej.

.

.

Ta wysokiej wydajności maszyna przemysłowa z portale CNC jest specjalnie zaprojektowana do wiercenia i oznakowania elementów płyty i blachy metalowej.Wykorzystuje się do produkcji wyrobów z tworzyw sztucznych, w tym wyrobów z tworzyw sztucznych, oferuje dedykowaną kompatybilność z obróbką flans, dysków, pierścieni, płyt płaskich i podobnych elementów.Podstawowym wymogiem jest, aby grubość obrabiarków ściśle spełniała ustalone wcześniej skuteczne specyfikacje obróbki maszyny..

W zakładach wytwarzających konstrukcje stalowe urządzenia te wykonują precyzyjne operacje wiercenia i frezowania na płytkach konstrukcyjnych i komponentach łącznikowych,ustanawiające solidne podstawy stabilnego montażu ram stalowychW sektorze energii wiatrowejW celu zapewnienia wysokiej precyzji rozwiązań obróbkowych dla wież i flans turbiny wiatrowej, firma dostarcza proces krytyczny, który zapewnia, że te elementy mogą wytrzymać trudne warunki środowiskowe (np.W przypadku projektów budowy mostów urządzenia przetwarzają łączniki mostów i uchwyty podtrzymujące, umożliwiając tworzenie stabilnych, stabilnych, stabilnych, stabilnych, stabilnych, stabilnych, stabilnych, stabilnych, stabilnych, stabilnych, stabilnych, stabilnych, stabilnych, stabilnych, stabilnych, stabilnych, stabilnych, stabilnych, stabilnych, stabilnych, stabilnych, stabilnych, stabilnych, stabilnych, stabilnych, stabilnych.trwałe połączenia zaprojektowane w celu wytrzymania obciążeń dynamicznych przez całą przedłużoną żywotność mostu.

Twoja wiadomość musi mieć od 20 do 3000 znaków!

Twoja wiadomość musi mieć od 20 do 3000 znaków! Proszę sprawdzić email!

Proszę sprawdzić email!  Twoja wiadomość musi mieć od 20 do 3000 znaków!

Twoja wiadomość musi mieć od 20 do 3000 znaków! Proszę sprawdzić email!

Proszę sprawdzić email!