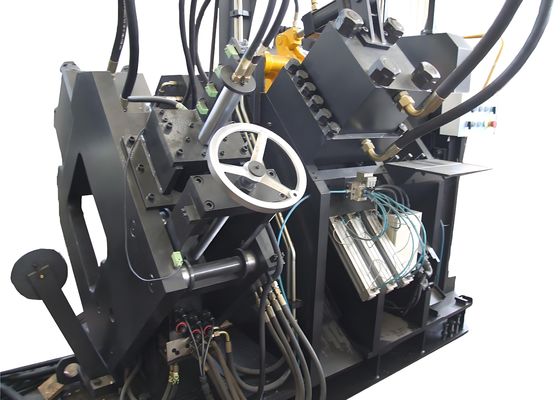

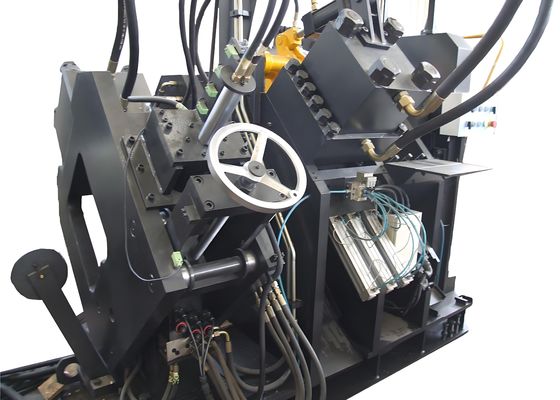

Wodny system chłodzenia hydrauliczny CNC Perforacja, znakowanie i strzyżenie

Przemysł stosowany:

Maszyna ta jest specjalistycznym sprzętem zaprojektowanym do drukowania, oznakowania i obcinania stali kątowej w sektorze wieży stalowej kątowej.wspieranie efektywnej produkcji w produkcji wież, zapewniając zgodność z normami branżowymi i zwiększając wydajność operacyjną.

Specyfikacje:

| Funkcje |

Wyrobki z tworzyw sztucznych (z wyłączeniem tworzyw sztucznych) |

| Wielkość kąta ((mm) |

40×40×3 140×140×12 |

| Maksymalna długość plamy (m) |

12 |

| Maksymalna długość końcowego materiału (m) |

10 |

| Maksymalne przebicie (promiar х grubość) (mm) |

Φ26×12 ((Materiał:Q345 510N/mm2) |

| Cioski po stronie |

2 |

| Siła uderzeniowa (kN) |

630 |

| Siła oznaczania (kN) |

630 |

|

Siła cięcia (kN)

|

1800 |

| Grupa liter oznakowania |

4 |

| Liczba liter na grupę |

12 |

| Rozmiar litery (mm) |

14×10×19 |

| Tryb cięcia |

Pozostałe maszyny |

| Osi CNC |

3 |

| Prędkość kąta podawania (m/min) |

80 |

| Metoda chłodzenia układu hydraulicznego |

Chłodzenie wodne |

| Dokładność obróbki |

Zgodność z GB2694 |

| Funkcja programu |

Wprowadzenie przez klawiaturę i interfejs USB |

| Wymiar ((mm) |

28000×6500×2200 |

Skład produktu:

Maszyna składa się głównie z przenośnika poprzecznego, obracającego się systemu ładowania, przenośnika z napędem, przenośnika z napędem CNC, jednostki przebicia, jednostki oznakowania, jednostki cięcia, przenośnika rozładunkowego,oraz hydrauliczne, systemów elektrycznych i pneumatycznych, między innymi.

Charakterystyka produktu:

1. Przyjmuje technologię CNC i serwo silnik, charakteryzujący się wysoką wydajnością i stabilną precyzją obróbki.

2Każda strona jest wyposażona w trzy zestawy ciosów i matri, które mogą pomieścić trzy rodzaje ciosów o różnej średnicy.Trzy zestawy form można przenieść wspólnie pod kontrolą PLC do regulowania znaku zwrotnego ciosów.

3Komputer jest wyposażony w interfejs chiński/angielski, zapewniający łatwą obsługę, i może wyświetlać rysunki obrabiarków.i może bezpośrednio wykorzystać dane programu generowane przez oprogramowanie lofting. Podczas edycji programów należy podać tylko rozmiar obrabiarkę, średnicę otworu, znak z tyłu i ilość obrabiarkę.

4. Jednostka oznakowania przyjmuje zamkniętą strukturę ramy o doskonałej sztywności.Oznaczanie znaków zwrotnych można ustawić dowolnie.

5Cylindry do bicia, znakowania i obcinania są większe; wózek NC jest nowego typu o zwiększonej wytrzymałości, a zaciski są bardziej wytrzymałe.

Te próbki, obejmujące wspólne specyfikacje i scenariusze obróbki w przemyśle wież stalowych kątowych, pozwalają użytkownikom bezpośrednio zbadać jakość obróbki sprzętu, precyzjęi rzemiosłoFunkcjonują one jako konkretny punkt odniesienia do oceny jego wydajności i przydatności do specyficznych potrzeb produkcyjnych.

Jest on przeznaczony głównie do wiercenia i pieczętowania dużej wielkości, wysokiej wytrzymałości stali kątowej stosowanej w wieżach linii przesyłowych,i jest szeroko stosowany w różnych scenariuszach podczas budowy i utrzymania infrastruktury przesyłowej energii.

W budowie linii przesyłowych ultrawysokiego napięcia (UHV), gdzie wieże muszą wytrzymać ekstremalne warunki pogodowe i duże obciążenia,To urządzenie odgrywa kluczową rolę w przetwarzaniu elementów stalowych, które tworzą główne ramy wież.Specjalnie wykonuje operacje wiercenia i pieczętowania dla stali kątowej wykorzystywanej w kadłubach wieży, skrzyżowanych ramionach i innych kluczowych częściach konstrukcyjnych,zapewnienie precyzyjnych wymiarów i silnych połączeń w celu zagwarantowania ogólnej stabilności wież.

Twoja wiadomość musi mieć od 20 do 3000 znaków!

Twoja wiadomość musi mieć od 20 do 3000 znaków! Proszę sprawdzić email!

Proszę sprawdzić email!  Twoja wiadomość musi mieć od 20 do 3000 znaków!

Twoja wiadomość musi mieć od 20 do 3000 znaków! Proszę sprawdzić email!

Proszę sprawdzić email!